Description

Here are some common uses of contactors:

Motor Control:

Contactors are extensively used for controlling electric motors. They provide a means to turn motors on and off, allowing for efficient and safe operation. Contactors are often used in industrial machinery, HVAC systems, elevators, and escalators to control motor-driven components.

Lighting Control:

In larger buildings or facilities, contactors are used to control lighting circuits. They enable the centralized control of multiple lighting circuits, allowing for automated switching, scheduling, and energy management. Contactors can handle high electrical loads, making them suitable for controlling large lighting systems.

Heating and Cooling Systems:

Contactors are utilized in HVAC systems to control the operation of heating and cooling equipment. They enable the switching of high-power elements like heating elements, compressors, and fans, allowing for precise temperature control and efficient operation.

Power Distribution:

Contactors play a crucial role in power distribution panels and switchboards. They help manage the flow of electrical power by connecting and disconnecting circuits, protecting against overloads and short circuits. Contactors are often used in conjunction with circuit breakers and fuses to ensure electrical safety.

Industrial Control Systems:

Contactors find widespread use in industrial control systems, such as conveyor systems, pumps, cranes, and manufacturing machinery. They provide the necessary switching capability to control the operation of these systems, allowing for efficient production processes and increased safety.

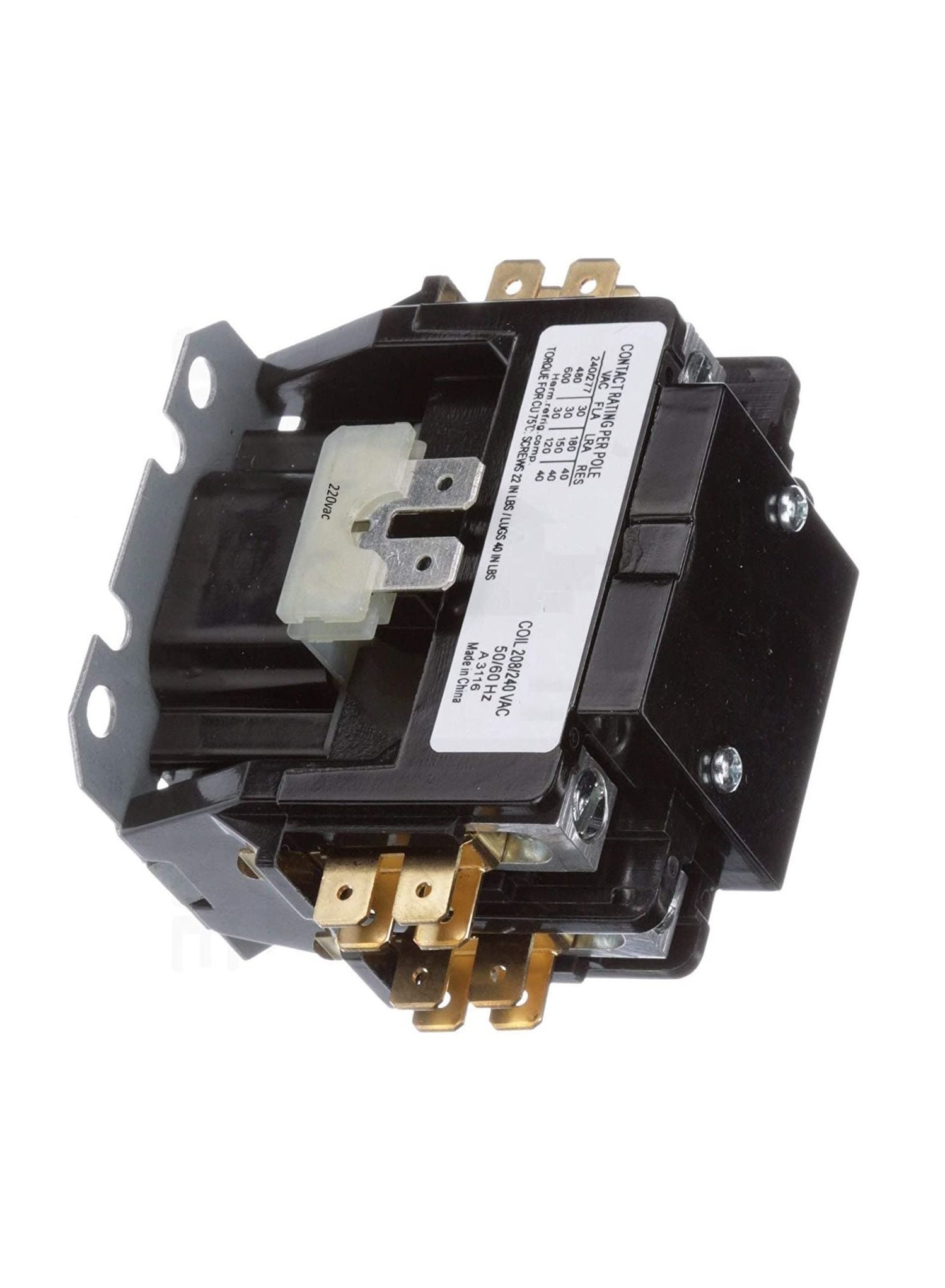

The descriptions you provided refer to different types of contractors based on their pole configuration and voltage ratings.

2 Pole 220V Contactor:

This contactor has two poles, which means it has two sets of contacts. It is designed to handle a voltage rating of 220V. These contactors are commonly used in applications where a two-phase power supply or a single-phase with neutral power supply is present.

2 Pole 24V Contactor:

Similar to the 2 pole 220V contactor, this contactor also has two poles but is designed to operate at a voltage rating of 24V. These contactors are typically used in low-voltage control circuits, often found in automation and control systems.

3 Pole 220V Contactor:

The 3 pole contactor has three sets of contacts and is rated for a voltage of 220V. These contactors are commonly used in three-phase electrical systems where three power lines are present. They are often employed for controlling motors or other three-phase loads.

3 Pole 24V Contactor:

This contactor, like the 3 pole 220V contactor, has three poles but operates at a voltage rating of 24V. They are utilized in low-voltage control circuits, similar to the 2 pole 24V contactor, but provide three sets of contacts for controlling three-phase loads.

Air Conditioners

Air Conditioners Heaters & Elements

Heaters & Elements Copper Coil & Tubes

Copper Coil & Tubes HVAC & Ducting

HVAC & Ducting Refrigeration & Chillers

Refrigeration & Chillers Rewinding Materials

Rewinding Materials Tools & Safety products

Tools & Safety products Washing Machines

Washing Machines

Reviews

There are no reviews yet.